Unseen Dangers: Ultrasonic Testing for Fire Suppression Systems Benefits

Enhancing Fire Safety: The Power of Ultrasonic Testing for Fire Suppression Systems

In the complex landscape of modern commercial and industrial facilities, fire suppression systems stand as the silent guardians, meticulously designed to protect lives and property. While often out of sight, their operational readiness is paramount.

Traditional inspection methods for these critical systems can be disruptive, time-consuming, and even wasteful. This is where Fire Suppression System Ultrasonic Testing emerges as a revolutionary solution, offering a non-invasive, highly effective approach to ensuring the integrity and reliability of these vital fire protection networks.

The Invisible Threat: Why Internal Inspections Matter

Fire sprinkler systems, since their widespread implementation in the 1800s, have saved countless lives and billions in property damage. These systems bring water through a network of pipes, often sitting idle for years. However, this dormant water, often containing dissolved minerals and chemicals, can react with the metal pipes, leading to internal corrosion, rust, and the accumulation of deposits.

These internal issues are invisible from the outside but can severely compromise the system’s ability to perform when needed. Corrosion can thin pipe walls, leading to leaks, or create blockages that impede water flow, rendering sprinkler heads ineffective during a fire event.

The National Fire Protection Association (NFPA) 25 bulletin mandates frequent visual inspections and an internal inspection of system pipes at least every five years, underscoring the critical need to identify these hidden threats.

Traditional Inspection: Costly, Disruptive, and Inexact

For years, the standard method for inspecting the interior of fire sprinkler pipes involved a laborious and intrusive process:

- System Shutdown: The entire fire suppression system would need to be taken offline, interrupting normal building operations and potentially requiring a fire watch.

- Draining: Thousands of gallons of water would be drained, leading to significant water waste and logistical challenges.

- Sample Removal: Sections of the pipe would be cut out and physically examined for corrosion or blockages. This “needle in a haystack” approach meant critical decisions were often based on limited, potentially unrepresentative samples.

- Repair and Recharge: After inspection, new pipe sections would be welded in, and the system re-pressurized and recharged, with seals checked for leaks.

This traditional method is not only costly and disruptive but also inexact, as it only provides a snapshot of isolated areas, potentially missing critical issues elsewhere in the extensive pipe network.

Ultrasonic Testing for Fire Suppression Systems Advantages: A Non-Invasive Revolution

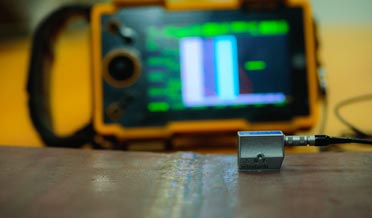

Drawing on principles similar to medical ultrasounds, ultrasonic testing for fire suppression systems utilizes high-energy sound waves to create an internal image of the pipes without any need for shutdown, draining, or cutting. This innovative Ultrasonic Testing for Fire Suppression Systems technology offers a multitude of benefits:

- Non-Invasive and Non-Destructive: The system remains online and operational throughout the inspection, ensuring continuous fire protection for your facility. There’s no messy draining or disruptive demolition.

- Comprehensive Assessment: Ultrasonic testing can scan entire pipe networks, providing a thorough understanding of internal conditions, unlike traditional methods that rely on limited samples. It can detect:

- Cracks or anomalies

- Pitting corrosion that weakens pipe walls

- Scaling corrosion that creates blockages

- Trapped air or water within the system

- Remaining wall thickness and areas of wall degradation

- Cost and Time Efficiency: By eliminating shutdowns, draining, and extensive repairs from sample removal, ultrasonic testing significantly reduces time and labor costs. Inspections can often be completed during normal business hours.

- Improved Accuracy and Data: The technology provides detailed, measurable data and a valuable “map” of the pipe’s integrity. This information can be compared over time to track corrosion rates and identify problem areas years before they lead to failure.

- Compliance and Liability Reduction: Catching corrosion or blockages early helps facilities remain compliant with fire codes and reduces liability by preventing potential system failures.

- Versatility: Ultrasonic testing is effective on both wet and dry sprinkler systems, and various pipe materials, including steel and galvanized pipes.

Partnering for Proactive Fire Safety with Fire-Safe

Fire-Safe Protection Services, LP is at the forefront of implementing this advanced technology. With extensive experience and specialized equipment, Fire-Safe provides comprehensive Ultrasonic Testing for Fire Suppression Systems for fire sprinkler systems. Our expert technicians are trained to accurately interpret the high-energy sound wave patterns, identifying internal issues like corrosion and blockages with a high degree of sensitivity.

By choosing Fire-Safe’s Ultrasonic Testing for Fire Suppression Systems, facility managers can move beyond reactive repairs to a proactive maintenance strategy. This ensures consistent compliance with safety regulations, extends the lifespan of their fire suppression systems, and ultimately provides peace of mind, knowing that their property and occupants are safeguarded by a truly reliable and fully functional fire protection network. Don’t wait for a crisis to discover hidden problems; embrace the future of fire safety with Ultrasonic Testing for Fire Suppression Systems.

Contact Fire Safe Protection Services today at 713-722-7800 or visit our online form, and we will be in contact as soon as possible about your Ultrasonic Testing for Fire Suppression Systems questions.