Ultrasonic testing offers a less invasive, more cost-effective testing method that can be used during inspections or as a routine maintenance check on your fire suppression systems. There is no shutdown time, it is non-destructive, and system drainage is not required.

According to the United States Fire Administration (USFA), recent trends show commercial building fires are up 26% in the last 10 years resulting in over 100,000 fires in 2018 alone.

According to the United States Fire Administration (USFA), recent trends show commercial building fires are up 26% in the last 10 years resulting in over 100,000 fires in 2018 alone.

Proper testing and inspections are vital to maintaining the safety and functionality of full-function fire alarm systems, automatic fire sprinkler systems, and suppression systems in the event of a fire. When these systems are properly maintained they are extremely effective in eliminating and extinguishing elements of fire, as well as notifying occupants of emergency situations.

Ultrasonic testing provides a more thorough inspection with improved identification of current system conditions and corrosion trends. The benefits of Ultrasonic testing include:

If Ultrasonic testing reveals corrosive problems within a sprinkler system, resolution recommendations to restore the reliability and longevity of your system can be made with confidence. Including these potential steps:

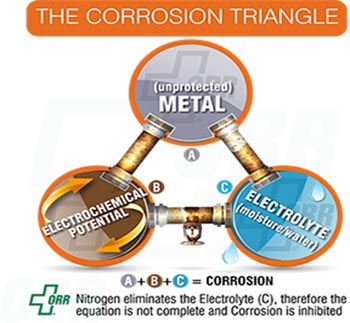

Corrosion is one of the most common causes of fire sprinkler system malfunction or failure. Oxidation of the metal inside the piping of the fire sprinkler system creates solid masses that corrode. Corrosion can present itself in both wet and dry pipe sprinkler systems and both galvanized and steel piping.

Corrosion is typically not visible from the outside and can go unnoticed until the time of catastrophic failure. Once corrosion starts, it can cost thousands of dollars in repairs.

Although you cannot eliminate 100% of corrosion in your fire sprinkler system, there are steps that can reduce the amount of corrosion in your system.

Ultrasonic testing from Fire Safe allows the fire sprinkler system pipe wall to be externally tested to determine the extent of any deterioration from corrosion or any other breakdown in the integrity of the pipe wall. Ultrasonic inspection benefits:

Fire Safe Protection Services can conduct internal or external pipe Ultrasonic Testing inspections to keep your facility in compliance with code and reduce liability by catching early signs and characteristics of corrosion. We offer ultrasonic testing, which will provide full wet and dry fire sprinkler pipe scans to examine entire systems, corrosion, and pipe thickness. Testing can usually be accomplished during normal working hours. Contact us to set up a time for a free consultation.